THE RIGHT TOOL MAKES ALL THE DIFFERENCE

LOADCELLS

The Model 3000 Load Cell is constructed from a high-strength steel or aluminum annulus with electrical resistance strain gauges forming a Wheatstone Bridge circuit. Half the gauges measure vertical strains, and the other half measure circumferential strain. The load cell features an outer shell for protection, waterproofing with o-rings, and a Kellem’s grip strain relief for cable security. The six-conductor cable with individually shielded twisted pairs connects to the GK-502 Readout Box using a remote sensing technique. Figure 3 illustrates a typical strain gauge load cell.

GEOKON LOADCELLS

(Electrical Resistance) | Model 3000

Load Cells (Electrical Resistance) | Model 3000

The Model 3000 Load Cell is made from an annulus of high-strength steel or aluminum, with electrical resistance strain gages in a Wheatstone Bridge configuration.

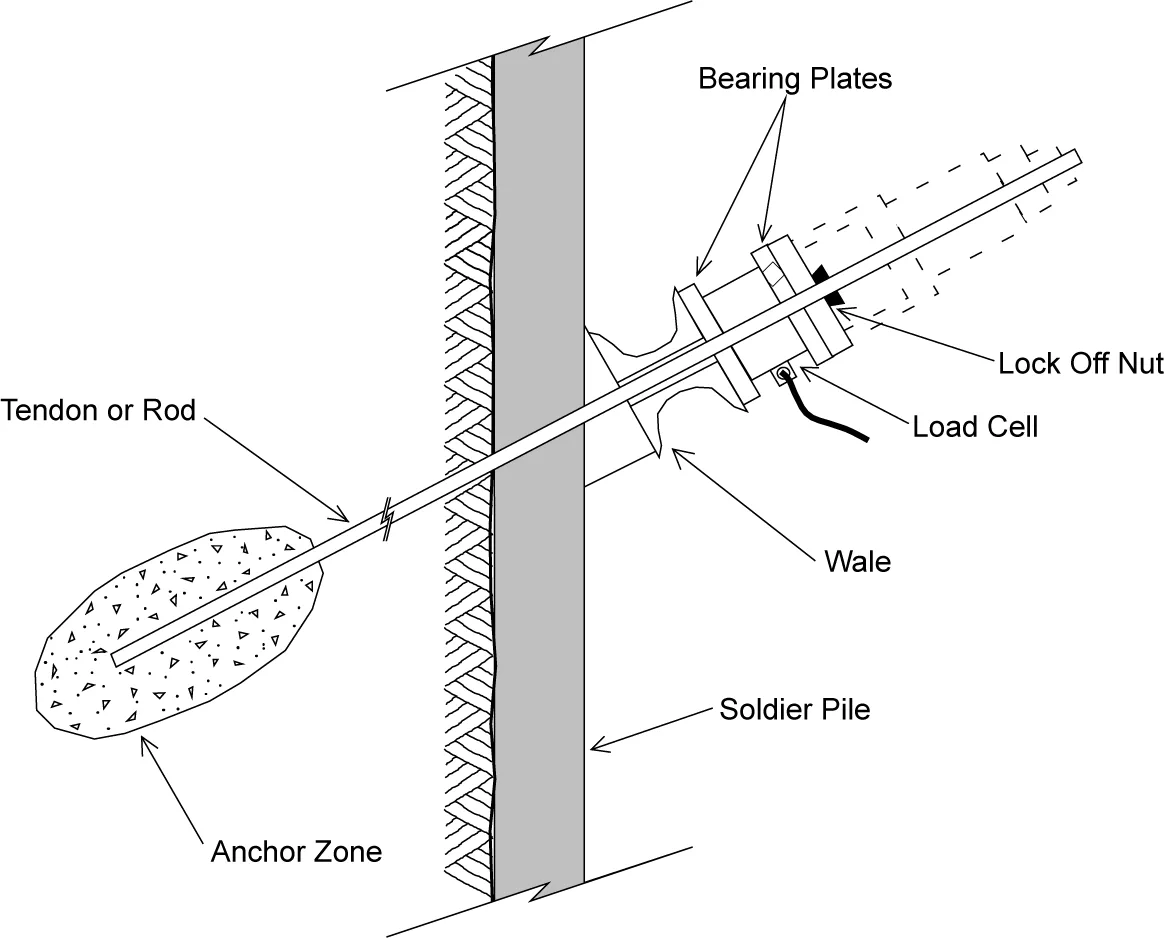

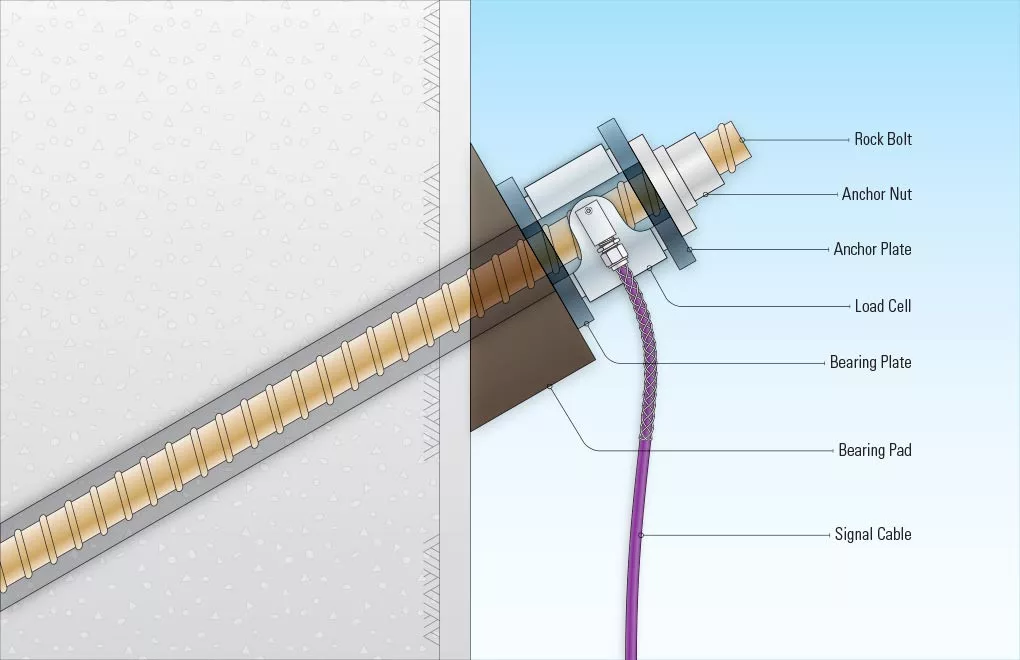

The load cell is designed primarily for use on tiebacks and rockbolts, although they may be used during pile load tests and for monitoring loads in crosslot struts and tunnel supports, etc. In most cases, the load cells are used in conjunction with a hydraulic jack and bearing plates.

Specifications

- Rated Capacities¹

- 100 to 10,000 kN

- Over Range

- 150% F.S.

- Resolution

- 0.025% F.S.

- Accuracy²

- ±0.5% F.S.

- Temperature Range −20°C to +80°C

- Internal Diameters mm

solid, 25, 50, 75, 100, 125, 150, 200, 250

The Model 3000 Load Cell is made from an annulus of high strength steel or aluminum. Electrical resistance strain gauges are cemented around the outside of the annulus and connected in a Wheatstone Bridge circuit. Half the gauges measure vertical strains, the other half measure circumferential strain.

An outer shell protects the gauges from damage and o-rings on either side of the gauges ensure that the load cell is fully waterproof. The cable is attached to the cell through a waterproof gland. A Kellem’s grip strain relief prevents the cable from being pulled out of the cell. Cables have thick PVC jackets and can be terminated in a 10-pin connector to mate with the GK-502 Readout Box. Figure 3 below shows a typical strain gauge load cell.